- Hard Chrome Plated Rods Supplier & Manufacturer in India

- Induction Hardened Chrome Plated Rod and Bar Manufacturer in India

- Peeled Ground Bars Manufacturer in India

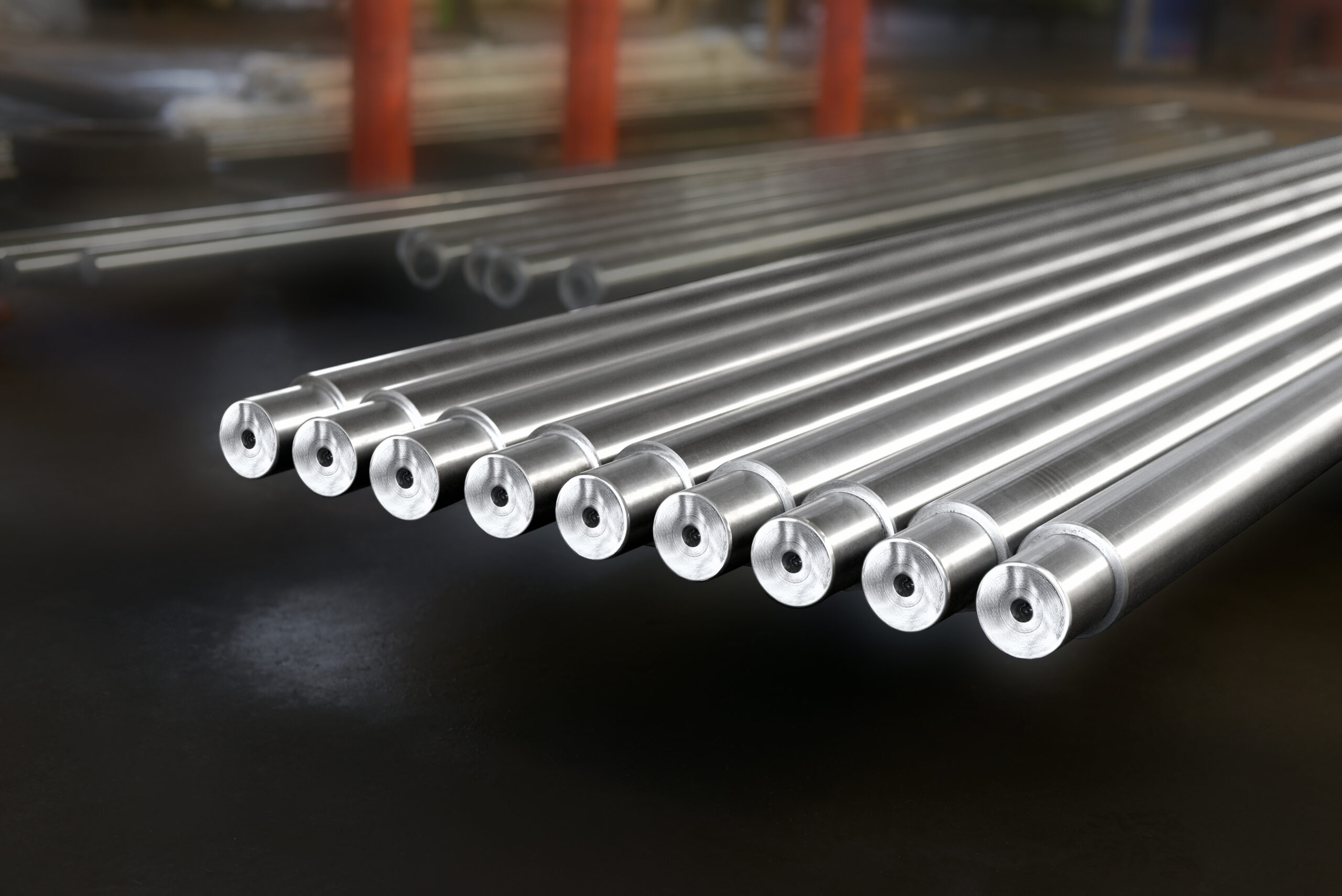

- Guide Bars Manufacturer in India

- Tie Bar Nuts Manufacturer for Injection Molding in India

- Pins Manufacturer in India

- Shaft Manufacturer in India

- Hydraulic Cylinder Piston Rod Manufacturer in India

Overview

The purpose of the chainsaw guide bar, which is made of high-quality, very resistant chrome molybdenum steel, is to accurately guide the saw chain across the object you are cutting with the least amount of friction loss. Guide bars convert the chainsaw’s motor power into cutting efficiency along with the sprocket and saw chain.

Chainsaws are guided precisely and with little friction loss by guide bars. They must handle the most challenging tasks without warping. The Rollomatic and Duromatic, the two fundamental types, were created to address various needs and application domains. Rollomatic bars are best used on a regular basis. Earlier, Windsor guide bars were quite popular as they were a bit lighter than Oregon and Stihl.

Tecnical Specification

| Material of Construction | : | Alloy & Carbon Steel; C45, EN8-D, EN9, EN19, EN24, EN31, Stainless Steel 300 & 400 Series, Aluminium & Others |

| Diameter | : | 12 mm to 500 mm |

| Length | : | Upto 6000 mm |

| Straightness | : | Approximately 0.1 mm/ meter |

| Surface Roughness | : | Approximately 0.1 Ra to 0.4 Ra |

| Run Out | : | Approximately 20 to 40 Microns |

| Tolerances | : | f7,f8,h6,h9,g6, & others as required(ISO Tolerances). |

| Chrome Plating Thickness | : | 20 to 200 microns/ side |

| Chrome Hardness | : | 850 HV to 1100 HV |

| Induction Hardness & Depth | : | Upto 65HRC in depth of 2 to 5 mm per side. |

Packaging

For domestic, within Ahmedabad – oiling, bubble wrapping & stretch film. For domestic, outside Ahmedabad – oiling, corrugated tube, bubble wrapping, hessian cloth, stretch film & wooden box if needed. For exports, anti-rust oil is on material and packed first by cardboard sleeve then in steel frame wooden box & pallets if needed.

Test Certificate

All goods will be sold with material test certificates to ensure proper quality from standard processing mills.

Inspection Report

Farmson engineers is very keen on quality & so before the material is dispatched, the material is passed through our QC department where it is inspected thoroughly & dispatched with our inspection report.

Our Product

Being the leading chrome plated rod manufacturers, we manufacture Burnished Hard Chrome Plated Rods, Induction hardened Chrome Plated Rods and Peeled Ground Bars. Our customised products include Guide Bars, Tie Bars and Nuts, Pins, Shafts and Piston Rod for Hydraulic Cylinder.

Download Our Brochure

Industries we Serve

We serve to a wide variety of industries including Injection Moulding, Printing & Rotogravure, Converting & Packing, Pneumatics, Hydraulics(Lift, Press, Cylinders), Pharmaceuticals, Blow Moulding, Agriculture, Marine, Defence, Chemical, Automotor, Oil & Gas, Construction, Textile, Extrusion and Stone Processing

WHY CHOOSE FARMSON ENGINEERS?

10+ Years of Experience

Specialized Technical Team

Service(Urgent Deliveries)

Everything in House

Quality Management System

Supply With Test Certificate

Why Choose Products from Farmson Engineers?

Farmson Engineers is a renowned name in the field of manufacturing, supplying, and exporting hydraulic equipment throughout India. Here are a few reasons why you should choose products from Farmson Engineers.

- About a decade of experience in the industry

- Uncompromised product quality

- Customized products available

- Use of advanced machinery and modern tools

- State-of-the-art manufacturing units

- Ready-to-use products

- Excellent customer service

- Superior post-sales service

- Competitive pricing structure

- Options for bulk orders

- Very quick turnaround time for delivery

So, whenever you are planning to buy premium quality guide bars, you can definitely reply on Farmson Engineers for all your current and future industrial demands

Customer Reviews

Looking for our product? or have any query?

Please contact us now.

FAQs

Some of the most frequently asked questions which comes from people from across the world who enquire about the guide bars are discussed below with relevant answers

The purpose of the chainsaw guide bar, which is made of high-quality, very resistant chrome molybdenum steel, is to accurately guide the saw chain across the object you are cutting with the least amount of friction loss.

First, the material for the guide bar is provided by a roll of stainless steel. The three components (two external and one internal) are cut out of the steel by immediately feeding it into a stamping press. After that, the layers are joined by an electro weld.

Keeping the conveyor belt under a certain limit, increasing the frictional force, and blocking the roll are some of the functions of a guide bar.

The Rollomatic and Duromatic are the two types of guide bars that are in use.

The purpose of a light guide bar, is to accurately guide the saw chain across the object you are cutting with the least amount of friction loss.